coldFALT

Cold/Wet Mix Plant

coldFALT

Cold/Wet Mix Plant

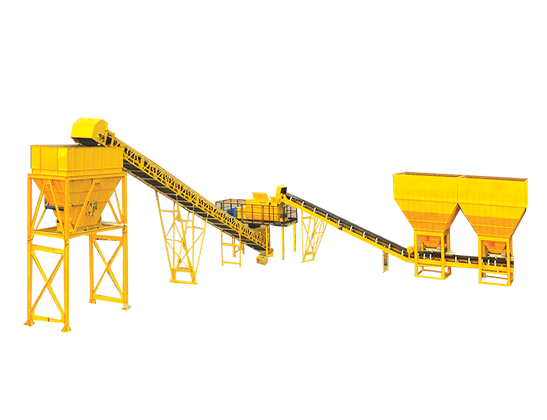

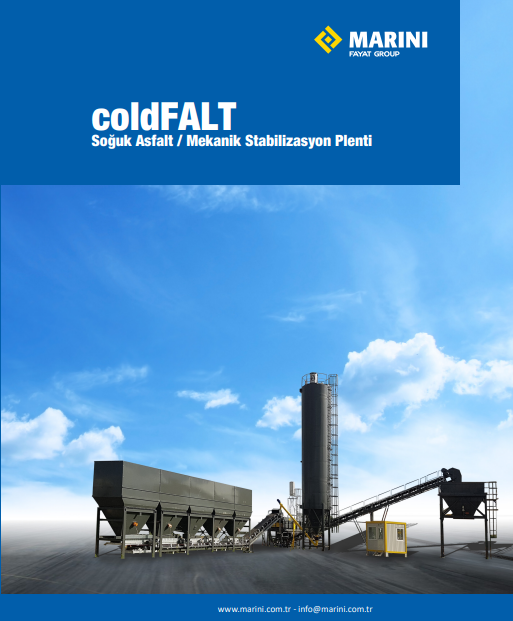

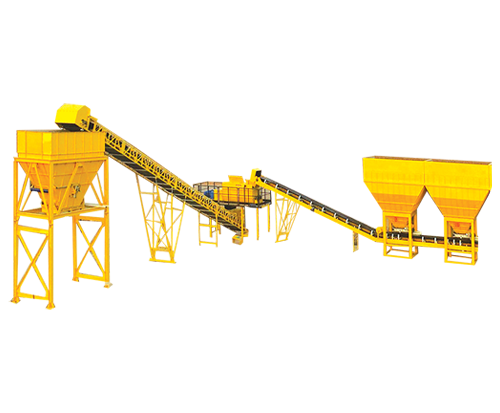

MARINI ColdFALT Cold/Wet Mix Plant, which is designed for mechanical stabilization, cement stabilization and cold asphalt mixtures, always runs smoothly even on the most challenging projects and never lets you down.

- Diversification of plants at different capacities in the range of 200-800t/h, in order to respond to different needs of road, railway, airport projects.

- Fully controlled production of mechanical stabilization, cement stabilization and cold asphalt mixtures in excellent quality.

- Specially designed twin shaft mixer for perfect mixing quality.

- Cold mix plants have been designed for various production of homogeneous cold/wet mixes with aggregate, water, cement, reclaimed asphalt, bitumen emulsion, foam bitumen.

- Thanks to standard production of coldFALT’s mixer, its arms, paddles, body parts with bolted anti-wear componentsand wear parts are very easy to replace and we can provide continuous spare part support.

- Dosing belt flow sensors stop the system automatically when aggregate feeding is interrupted.

- Capacity of dosing belts, ratio of cement, bitumen emulsion and foam bitumen in the mix can be adjusted from control cabin via frequency converter.

- Fully automatic control of production with optional PLC + computer control system, which also allows storage and reporting of all production data.

- Compact design fits into 40’ Open Top container (plants with 200-400t/h capacity) which provides easy and economic transportation.

Mechanical stabilization (water + aggregate), cement stabilization (water + aggregate + cement)

and cold mix asphalt (emulsion + aggregate + water, cement, recycled asphalt on demand).

Transport via standard trailer, the number of vehicles varies according to configuration.

and cold mix asphalt (emulsion + aggregate + water, cement, recycled asphalt on demand).

Transport via standard trailer, the number of vehicles varies according to configuration.

Mechanical stabilization (water + aggregate), cement stabilization (water + aggregate + cement)

and cold mix asphalt (emulsion + aggregate + water, cement, recycled asphalt on demand).

Transport via standard trailer, the number of vehicles varies according to configuration.

and cold mix asphalt (emulsion + aggregate + water, cement, recycled asphalt on demand).

Transport via standard trailer, the number of vehicles varies according to configuration.

Mechanical stabilization (water + aggregate), cement stabilization (water + aggregate + cement)

and cold mix asphalt (emulsion + aggregate + water, cement, recycled asphalt on demand).

Transport via standard trailer or 40’ Open Top container, number of vehicles/containers varies

according to configuration.

and cold mix asphalt (emulsion + aggregate + water, cement, recycled asphalt on demand).

Transport via standard trailer or 40’ Open Top container, number of vehicles/containers varies

according to configuration.

Mechanical stabilization (water + aggregate), cement stabilization (water + aggregate + cement)

and cold mix asphalt (emulsion + aggregate + water, cement, recycled asphalt on demand).

Transport via standard trailer or 40’ Open Top container, number of vehicles/containers varies

according to configuration.

and cold mix asphalt (emulsion + aggregate + water, cement, recycled asphalt on demand).

Transport via standard trailer or 40’ Open Top container, number of vehicles/containers varies

according to configuration.