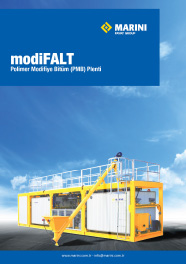

modiFALT

Polymer Modified Bitumen (PMB) Plants

modiFALT

Polymer Modified Bitumen (PMB) Plants

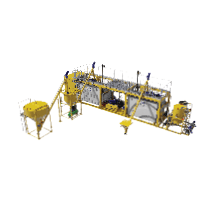

MARINI modiFALT Polymer Modified Bitumen Plant (PMB) is the ideal solution for all road projects with its high mill performance, compact design, ease of use and economic operation features. With its high production capacity, modiFALT can meet the needs of all road, railway, airport projects and special applications which requires modified bitumen usage.

- ModiFALT plants are specially designed for modification of bitumen (PMB) with granule polymer additives (SBS) and can meet all high capacity requirements of road construction and airport projects.

- Additionally, other types of bitumen modifiers such as EVA, crumb rubber etc. can be easily used for bitumen modification.

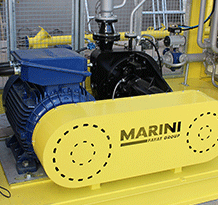

- modiFALT’s specially designed 160kW high shear mill is developed by the MARINI MAKİNA engineers for the best working performance with granule polymer types (e.g. SBS) and it ensures polymer modification with less than <0,3mm grain size in one pass.

- Long term and problem free working time thanks to the mill seal cooling system.

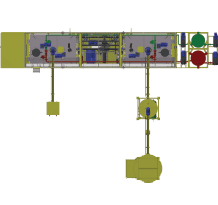

- Two tanks both equipped with twin agitators configuration ensures flexible batching process from 500kg to 5ton at desired number of pass.

- Precision weighing with loadcell integrated process tanks and strong blending with 2 pieces of 7,5kW agitator on each processing tank.

- A design that prevents agglomeration of the polymer particles thanks to thermal oil heating coils that surrounding the process tanks from sides and bottom.

- Optional; automatic polymer dosing system.

- Optional; manual or automatic dosing system for solid (ex. Sulfur powder) and liquid (ex. PPA) additives.

- Fully automatic control system with PLC + SCADA and computer controlled system.

- Trouble-free international transportation and assembly thanks to its standard dimensions.

Up to 40t/h, thermal oil heated, works with 2 automatic polymer dosing systems,

Transportation with 1x40’ Flat Rack and 1x40’ Open Top containers or 2 standard trailer.

Transportation with 1x40’ Flat Rack and 1x40’ Open Top containers or 2 standard trailer.

Up to 30t/h, thermal oil heated, works with 2 automatic polymer dosing systems,

Transportation with 2x40’ Open Top containers or 2 standard trailer.

Transportation with 2x40’ Open Top containers or 2 standard trailer.

Up to 20t/h, thermal oil heated, works with 1 manual polymer dosign systems,

Transportation with 1x40’ Flat Rack or 1 standard trailer.

Transportation with 1x40’ Flat Rack or 1 standard trailer.

Up to 20t/h, electrical heating, works with 1 manual polymer dosign systems,

Transportation with 1x40’ Flat Rack or 1 standard trailer.

Transportation with 1x40’ Flat Rack or 1 standard trailer.

Up to 15t/h, thermal oil heated, works with 1 manual polymer dosign systems,

Transportation with 1x40’ Open Top container or 1 standard trailer.

Transportation with 1x40’ Open Top container or 1 standard trailer.

Up to 15t/h, electrical heating, works with 1 manual polymer dosign systems,

Transportation with 1x40’ Open Top container or 1 standard trailer.

Transportation with 1x40’ Open Top container or 1 standard trailer.

Automatic Polymer Dosing System (OPTIONAL)

1-Polymer stock hopper with wide gate allows easy BigBag loading; equipped with vibrator motor and low level alarm sensor.2-Polymer weighing hopper; equipped with loadcell, pneumatic vibrator motor, pn. actuated discharge gate.

3-Screw conveyor for each polymer weighing & feeding system.

Weighing & Mixing Tanks

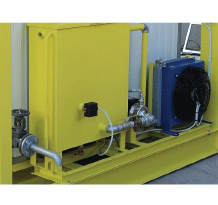

Two weighing-mixing tanks are equipped with twin agitators (2x7.5kW) that ensure proper polymer distribution and powerful mixing inside the batch tank. Agitators, as well as the seamless smooth internal lining of the tanks, prevent sticking of material on tank walls and agglomeration of bitumen. They are also equipped with 4x loadcells with digital weight indicator for precise weighing of the bitumen. All surfaces of the batch tanks, even the bottom, include heating in the outer layer. The bitumen/PMB inside the batch tank is sucked from the bottom surface to prevent any residual material.Control Cabin

User-friendly control cabin allows operator to work under comfortable conditions and protects the electric box & control system from dust, rain and humidity etc.Fully flexible, double control systems;

1-Semi-automatic

2-Full automatic control with PLC + computer control system (w/ SCADA) to suit varying operating conditions.

modiMILL (High Shear Mill)

160kW high shear mill with a high capacity which is designed and manufactured by MARINI TURKEY.Thanks to its unique design, developed by MARINI TURKEY engineers, which ensures 7 cutting stages at once; modiMILL high shear mill allows proper polymer modification of bitumen even in one pass.

Bitumen feeding pump with a capacity of 50m³/h, which transfers bitumen to the high shear mill prevents performance and capacity losses, so modiMILL is just focused on cutting process.

Easy adjustment of milling surface gap, allows the usage of different bitumen modifiers.

Liquid and Solid Dosing System (OPTIONAL)

As an option, modiFALT Polymer Modified Bitumen Plant can be equipped with liquid and / or solid additive dosing systems.Solid additives like sulphur flakes can be added through systems with manual gates, which are placed at the top of bitumen weighing and mixing tanks.

There are different systems for liquid additive dosing with heating, loadcell, flowmeter, etc. options according to additive specifications.

They are separately connected to both weighing and mixing tanks via pipelines. The pipelines might be equipped with heating systems according to requirements.

Dosing process is automatized and controlled by SCADA system. Liquid additive hoppers are equipped with loading and dosing pumps and also loadcells for precise weighing and dosing.